The Beauty of Pink Gold

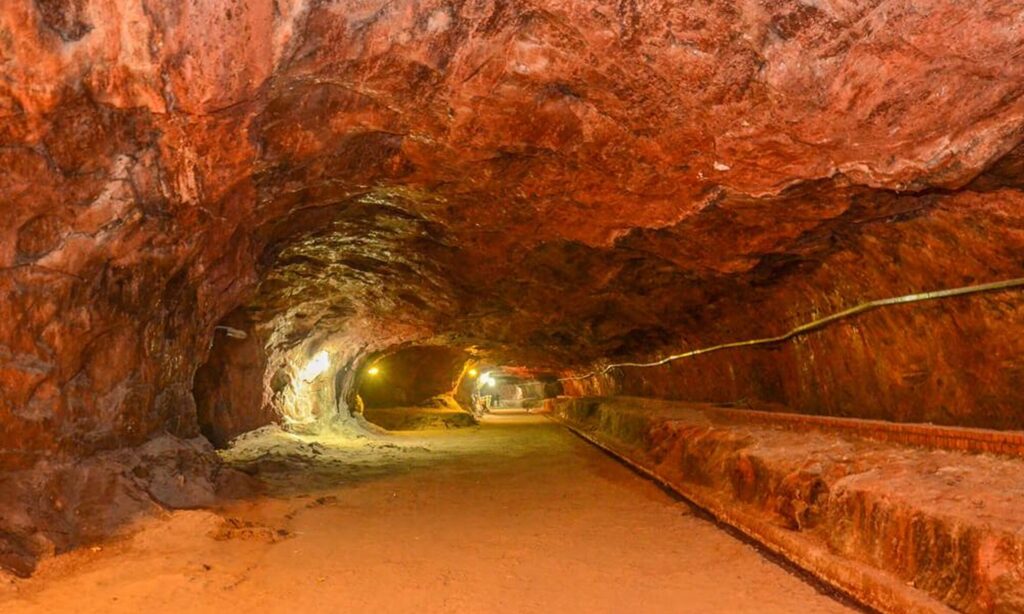

The pink shimmer of Himalayan salt has caught the attention of health enthusiasts, chefs, and wellness experts around the globe. But few know about the fascinating Himalayan salt mining process that begins deep in the majestic hills of Pakistan.

Known as “pink gold,” this mineral rich salt is mined from the Khewra Salt Mine, one of the world’s oldest and largest salt deposits. In this article, we’ll explore how Himalayan pink salt is extracted and processed, revealing the intricate steps and centuries old techniques behind it.

How Himalayan Salt Is Mined from Khewra

Himalayan salt mining takes place primarily in the Khewra Salt Mine, located in the Punjab region of Pakistan. Estimated to be over 800 million years old, the mine stretches across 110 square kilometers and holds billions of tons of salt reserves.

The process of how Himalayan pink salt is mined from Khewra Salt Mine in Pakistan is a careful balance of tradition, sustainability, and modern safety standards. Khewra remains an icon of mining excellence due to its safe and efficient techniques passed down through generations.

Step-by-Step Guide to the Mining Process

Let’s dive into the step-by-step guide to Himalayan pink salt mining techniques:

Survey and Planning

Engineers and geologists analyze rock stability, estimate salt reserves, and identify safe excavation zones. These plans ensure safety and maximize resource yield.

Drilling and Blasting

Using controlled explosives, miners create access points to the salt layers. This technique, called “room and pillar,” ensures that enough salt pillars are left to support the mine ceiling.

Salt Extraction

Large chunks of Himalayan salt are manually or mechanically removed. Miners often use saws and pickaxes to preserve the natural crystal formations.

Transportation

Extracted salt is loaded into carts or trolleys and transported through tunnels to the surface for further processing.

Sorting and Grading

On the surface, the pink salt is washed, dried, and graded based on color, purity, and size.

This detailed Himalayan salt mining process combines traditional knowledge with scientific precision to ensure high-quality salt production.

Mining Techniques Used at Khewra

Understanding the mining methods used in extracting Himalayan salt from Khewra offers insights into the care and craftsmanship behind each salt crystal:

Room and Pillar Mining: The safest and most sustainable method. Large “rooms” are carved out while “pillars” of salt are left untouched to support the structure.

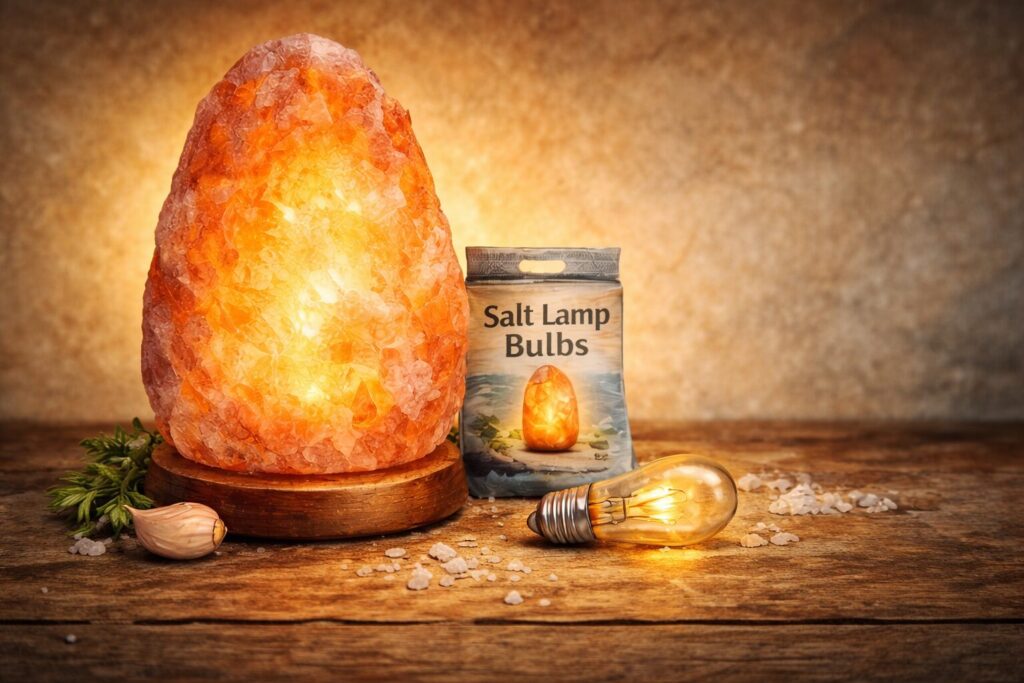

Hand Mining: For artisanal salt blocks and lamps, miners often extract salt manually to avoid fractures.

Mechanical Mining: Modern tools like drills, saws, and conveyors increase efficiency for large-scale commercial extraction.

These techniques minimize environmental damage and maximize resource longevity highlighting why Himalayan salt mining from Khewra is globally respected.

Harvesting and Processing for Export

Curious about how pink Himalayan salt is harvested and processed for export? Here’s the typical export preparation workflow:

Washing: Salt is rinsed in fresh water to remove impurities without disturbing its mineral content.

Drying: The salt is air-dried naturally or in low-temperature ovens to maintain its structure and color.

Grinding: Depending on use (culinary, bath, decor), the salt is ground to fine, medium, or large crystals.

Packaging: The salt is packaged in moistureres istant bags and bulk containers, ready for worldwide export.

Major importers of Khewra’s Himalayan salt include the USA, Europe, and Gulf countries, where it’s used in gourmet foods, spas, and holistic wellness centers.

Cultural and Economic Importance

The Himalayan salt mining process is not just about minerals it’s about identity. Khewra Mine is a national heritage site in Pakistan, attracting thousands of tourists every year. Salt miners, often working for generations, pass down their skills like a sacred legacy.

Economically, the export of Himalayan pink salt supports thousands of Pakistani families and plays a vital role in the regional economy. It’s a powerful symbol of how a unique mineral can carry the weight of both tradition and trade.

Sustainability in Himalayan Salt Mining

Modern Himalayan salt mining practices emphasize:

Zero-waste mining

Renewable energy integration

Eco-friendly packaging

Worker health and safety protocols

Khewra Salt Mine is also a model of sustainability, ensuring that pink salt extraction doesn’t compromise the environment or future resources.

The Legacy of a Unique Mineral

The Himalayan salt mining process is a testament to human ingenuity, patience, and respect for nature. From the depths of Khewra to kitchens and spas across the world, each crystal carries a story of legacy, labor, and luxury.

Whether you’re sprinkling it on a gourmet dish or soaking in a mineral rich bath, remember the journey of this pink gold began with Himalayan salt mining deep beneath the Pakistani mountains, harvested with care and polished by tradition.

FAQs

It is primarily mined in the Khewra Salt Mine in Punjab, Pakistan the second-largest salt mine in the world.

Through a combination of room and pillar mining, hand tools, and controlled machinery that ensures safe and efficient extraction.

Yes. Strict safety protocols, ventilation systems, and protective gear are in place to protect miners.

Its 84 trace minerals, natural pink color, and unrefined state make it a unique mineral prized globally for wellness and flavor.

It’s washed, dried, sorted, and packaged carefully to preserve purity, quality, and natural color before being exported worldwide.